World's Leading Bespoke Awning Manufacturer

Back in 1956 when George Morrison first established Morco blinds, close to what would eventually become the Thames Barrier, machinery for manufacturing our awnings comprised little more than that which would be today found in the average handyman's workshop. Hand saws, a large bench vice, a pedal operated sewing machine and sewing palms were the basics required to manufacture awnings back in the 1950's.

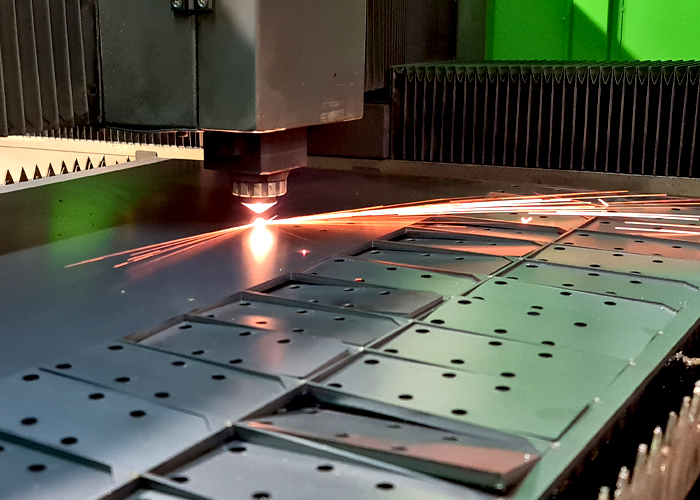

Over the years we have focussed on investment in appropriate machinery which has enabled us to be at the forefront of awning design and innovation. No longer are huge biceps required to bend Victorian awning arms - there is a digitally controlled robot which does the so accurately it is impossible to distinguish differences in pairs.

The pungent and unhealthy aroma of oil based paint has disappeared with the installation of a sealed powder coating plant providing unlimited colour shades to metal work in an iron hard finish which resists weather and wear.

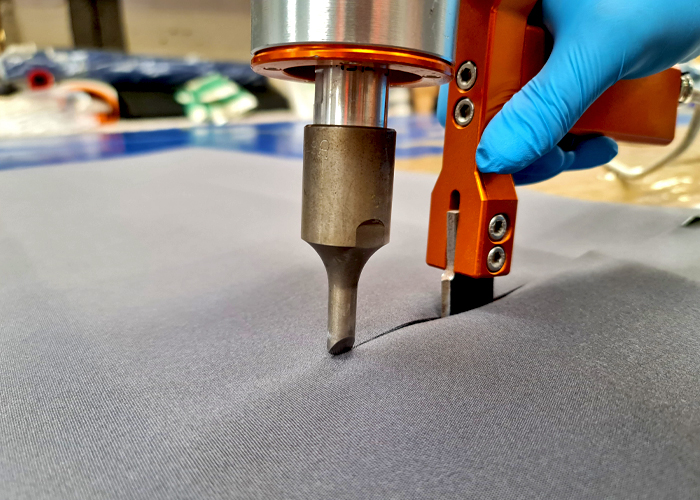

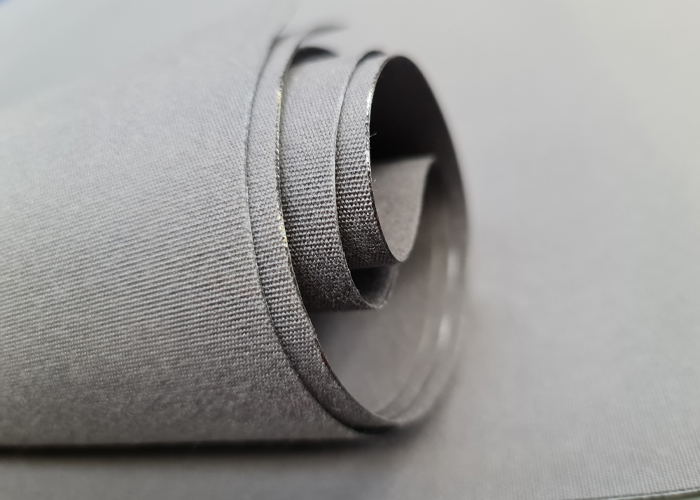

The sewing machines today effortlessly align covers to provide wrinkle free seams which are created just as fast as the bobbins can rotate and the covers can travel along the conveyor.

Last, but by no means least, is the digital RAGS® process we have developed for the decoration and branding of awnings which was previously handled by an artisan with a brush and "maulstick" to hold them steady. Though we do still apply 24 carat gold leaf by hand all other graphics are produced digitally with astonishing clarity and a colour range limited only by the designers imagination.

Morco – The Commercial Awning Experts

Professional awning solutions for leading brands and businesses across the UK, Europe & worldwide. Call our sales team on 020 8858 2083 or enquire online